A pallet racking storage system is made up of 2 basic parts: frames (or uprights), and beams (or cross beams). Frames are the vertical structures of a pallet rack system, and beams are the horizontal structures and what you place your pallets on.

Beams come in 2 basic designs:

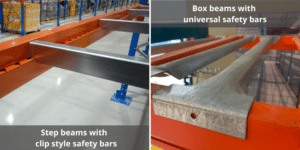

- Box Beams

- Step Beams

Box beams have a basic rectangular shape, similar to the shape of a 2X4 board with clips on the end to attach to a vertical frame.

Step beams, on the other hand, have (you guessed it!) a step in their design. Almost like an L-shape, with slots along the lower edge of the step.

To gain a better understanding of the beam designs, we put step beams, and box beams head to head against 3 factors to see who comes out on top.

Box Beam vs. Step Beam Round 1: STRENGTH

Box beams have always been the popular choice in the Canadian pallet racking market, and are preferred for their superior strength per square inch. Because of their basic rectangular shape, box beams are able to hold heavier loads compared to Step Beams, which have a more intricate design.

However, although Box Beams are stronger than Step Beams per square inch, this can be mitigated by simply getting a taller Step Beam, but this will increase the cost.

Because Step Beams can make up their strength with height, this is a tied round.

Box Beam vs. Step Beam Round 2: SUPPORT BARS

Pallet racking support bars, otherwise known as safety bars, are steel bars that run perpendicular to the rack beams in order to keep pallets or other products stored in the racking system from falling through. Box beams require universal safety bars, which have a U-shaped design on each end that is placed over the top of the box beam. The issue with this design is that clothing and products get snagged on the safety bar, causing minor damage.

Also, the safety bars take up space on the outside of the beam, an area that is commonly used for product identification labels. Additionally, safety engineers are more frequently requiring these types of safety bars to be bolted to the pallet racking beam, which keeps you from being able to freely adjust the safety bar if needed.

Step beams, on the other hand, require the use of clip-style safety bars. These safety bars fit neatly inside the step beam, and therefore the risk of snagging is greatly reduced. Additionally, you typically are not required to bolt in clip-style safety bars, which give you the flexibility to move them when needed.

Due to the advantages that clip-style safety bars have over universal safety bars, we will give this point to Step Beams.

Box Beam vs. Step Beam Round 3: ACCESS

Industrial racking systems here in Canada are often times equipped with box beams, rather than step beams. Therefore, as the laws of supply and demand dictate, box beams and their accessories are a lot easier to come by.

It does not mean that step beams are not widely available; it just means that if you are planning a very large warehouse racking system, lead time may be longer when supplying step beams over box beams.

For obvious reasons, this round goes to Box Beams.

Box Beam vs. Step Beam: FINAL SCORE

Like most things in life, it depends! It depends on many factors such as what you are storing, the size of your pallet racking system, your budget, and your project time frame.

Step beams and their clip-style safety bars will provide you with the ability to move the safety bars more freely, and decrease the probability of snagging due to their neat fit.

But, if you need a super-fast turnaround for your pallet racking system, you will probably have better luck with box beams due to their increased supply among warehouse storage equipment suppliers.

At Concept Storage, we stock a continuous supply from both box beams and step beams, along with their accessories, at our warehouse in Vaughan, Ontario.

We stock both new & used box beams, and step beams. Click here to see our current stock list.

For any other pallet racking questions, contact our sales professionals at Concept Storage Solutions Ltd.

by

by