Cold Storage Warehouse Solutions

Temperature requirements are often required when implementing cold storage warehouse solutions for pharmaceutical warehouses and food & beverage warehouses. These temperature requirements can often serve as a limitation to the type of storage system available to use. Thankfully, with recent innovations within the material handling industry, the availability and variety of options for cold storage warehouse solutions has greatly increased.

Types of Industrial Cold Storage Warehouse Solutions

Selective Pallet Racking for Cold Storage

Selective Pallet Racking can be used within a cold storage facility, as the integrity of the system will not be compromised given the low or freezing temperatures. Although selective pallet racking is an economical, and short lead time solution, it may not be the best solution in cold storage environment.

Often in the food & beverage industry, or pharmaceutical industry, the warehouse operations are governed by the strict expiry dates of the product stored in the facility. Therefore, pick rates and accessibility of the product are high. With selective pallet racking, the accessibility of products is not optimal compared to other solutions, and therefore in a warehouse where expiry dates are a large concern, selective pallet racking is may not be most optimal choice for cold storage warehouse solutions.

Economical

Selective pallet racking is the most low cost storage solution for cold storage warehouses

Fast Lead Time

Because of the standardization of selective pallet racking, leads times will be minimized

Lower Density, Lower Accessibility

Selective pallet racking will offer lower density, and lower accessibility compared to other solutions

Mobile Racking Systems for Cold Storage

Mobile racking systems offer high-density storage, while still maintaining high accessibility to the product. Cold storage solutions are available in a variety of mobile storage options, from powered or manual mobile racking, to powered or manual mobile shelving.

Mobile storage solutions for cold storage are installed on rails in the concrete floor, and take up the unused aisle space that conventional selective pallet racking would have otherwise left un-used. These mobile storage solutions are fully customizable and adaptable should requirements change over time.

When it comes to cold storage, powered or manual systems can work in environments such as walk-in freezer warehouses, or any temperature-controlled environment. Powered mobile storage systems will increase the accessibility of product, compared to a manual design. Therefore the powered option would likely be optimal when in a cold storage facility, where product turnover is high (due to expiry dates).

High Density

Mobile storage systems use up the aisle space that would typically be left empty

Customizable

Mobile Storage Systems are highly customizable to meet specific storage requirements

Accessibility

Accessibility can be optimized by using a powered option over a manual option

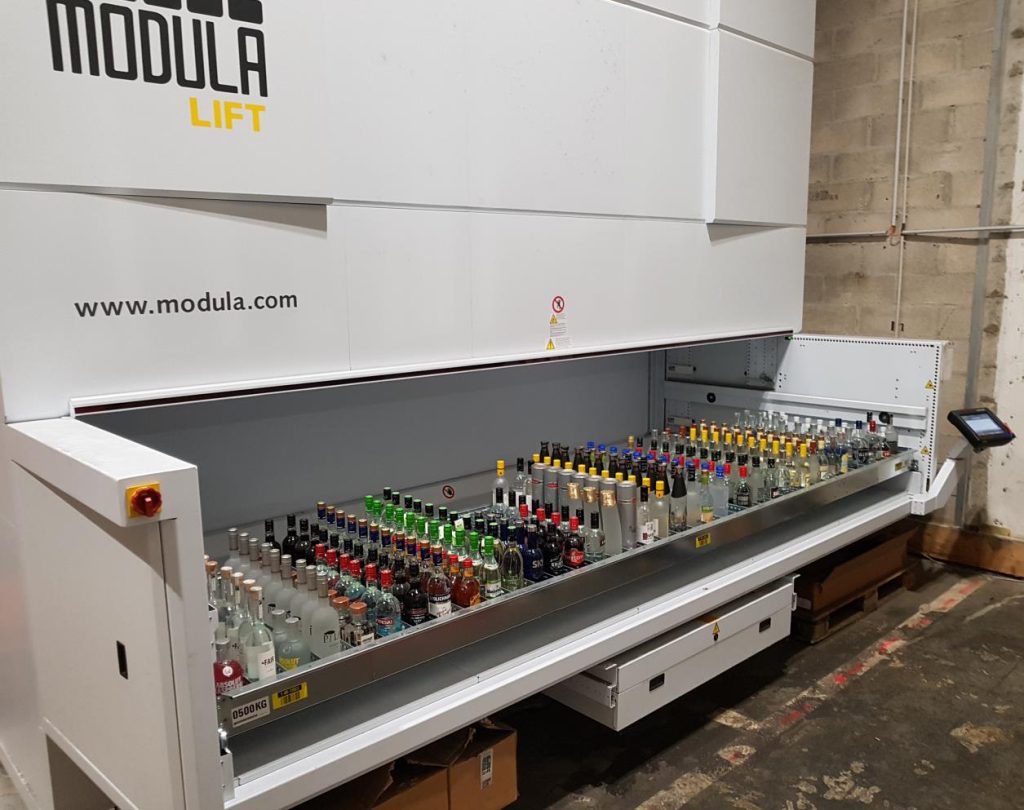

Vertical Lift Modules for Cold Storage

Vertical lift modules (VLMs) provide compact storage, and uses up the least amount of space compared to any other storage system currently on the market. With recent innovations made to VLMs, these systems are now available as either integrated within a temperature controlled storage facility, or equipped with its own thermal insulation and refrigeration systems to maintain the required temperatures. An insulated VLM contains independent windows that can be opened to retrieve the desired product, which means the operator has access to the bay without affecting the internal temperature of the rest of the system.

These vertical lift modules are designed to take into account not only the required temperatures but also humidity levels, ensuring that the quality of the products stored inside remains intact. Temperatures for the self-contained temperature controlled VLMs can maintain temperature from +2C – +40C, with humidity control of +- 2%.

High Density

Vertical lift modules provide the most dense storage solution by using vertical space, limiting required floor space to implement the solution

Accessibility

With carousels able to select and deliver products right to the operator, order picking with a VLM is efficient and concise

Self-Contained Refrigeration

VLMs have a self contained refrigeration and humidity control system, which is perfect for warehouses where temperature control is only needed only certain areas

by

by